BOS - Recipe User Guide

1. Overview

Available under the Smart Recipe system, this module provides complete control over raw material usage and recipe management for restaurants. It enables cost monitoring, loss tracking (e.g., spoilage, expired stock), food cost calculation, and integration with restaurant sales systems.

2. SET CONFIGURATION

Available under the SYS > Recipe System menu, this section is used to define essential configuration settings before using Smart Recipe. These settings include inventory timing, storage location, raw material formulation, recipe setup, and unit conversions to ensure accurate inventory and cost tracking.

2.1 Initial Configuration Setup

Available under SYS > Back Office Master >Recipe System, this section is for configuring foundational data required before using the Smart Recipe system effectively. This includes scheduling stock counting, defining storage locations, setting ingredient stock thresholds (Min/Max), formulating internal recipes, creating cooking recipes, converting units, and generating reports. These settings ensure that inventory is managed accurately, costs are calculated properly, and recipes function correctly across operations.

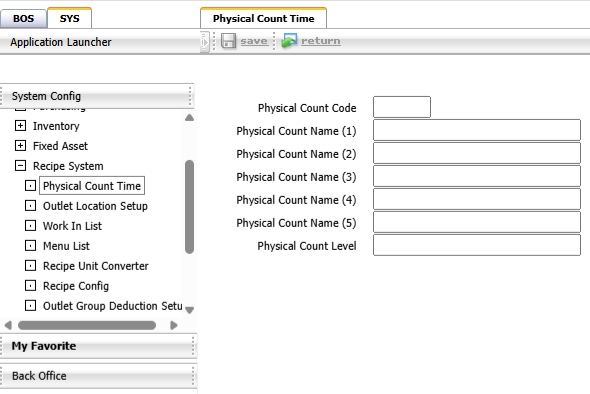

2.1.1 Counting Schedule:

Defines stock counting intervals to ensure timely and accurate inventory updates aligned with sales activity.

- Navigate to SYS > Back Office Master >Recipe System > Physical Counting Time

- Click 'New' and input the stock counting schedule

- Press Save

Note: Define appropriate schedule intervals to match actual sales frequency for cost accuracy.

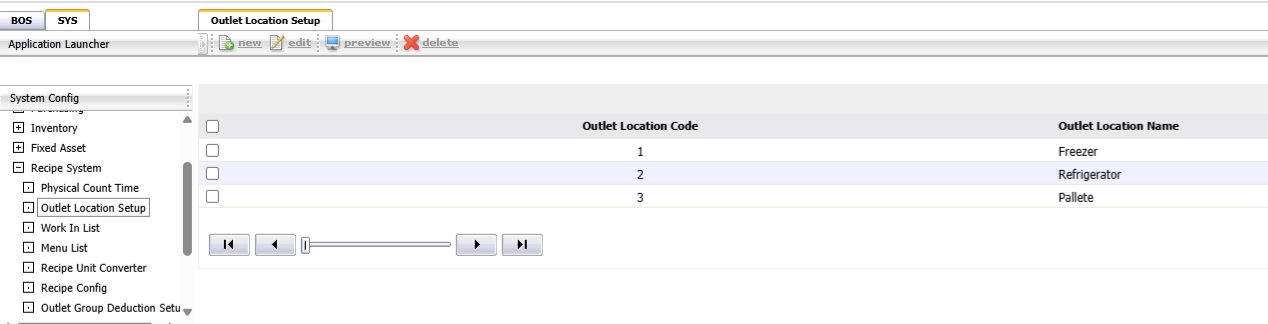

2.1.2 Determination of Storage Location:

Sets up storage areas for raw materials to ensure proper tracking and prevent inventory confusion.

- Navigate to SYS > Back Office Master > Recipe System > Outlet Location Setup

- Click 'New', fill in storage location details

- Press Save

Note: Clear separation of storage locations helps prevent confusion in inventory cuts.

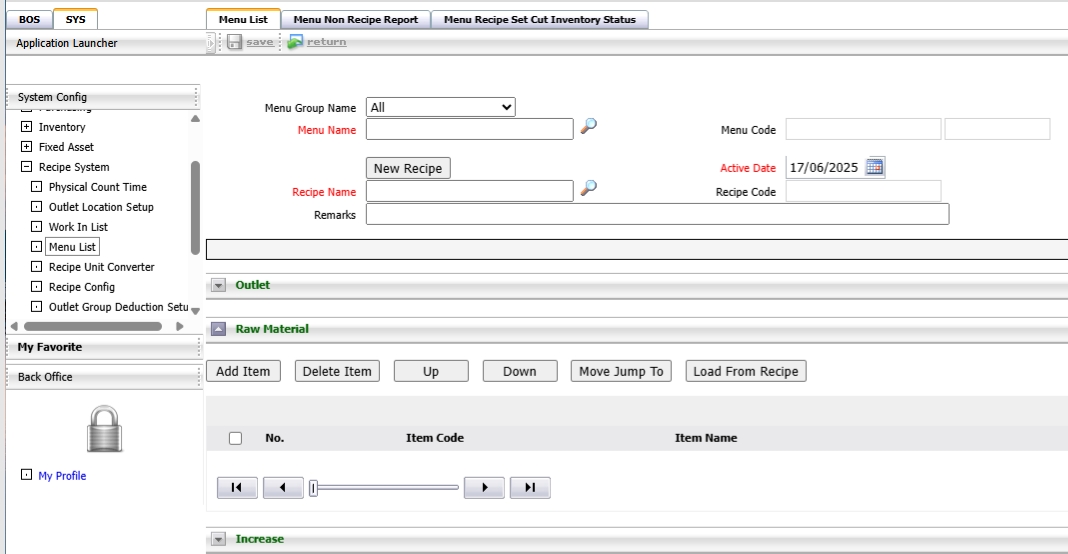

2.1.3 Formulating Raw Materials:

Creates internal formulas for raw material usage, including cost allocation and approval workflows.

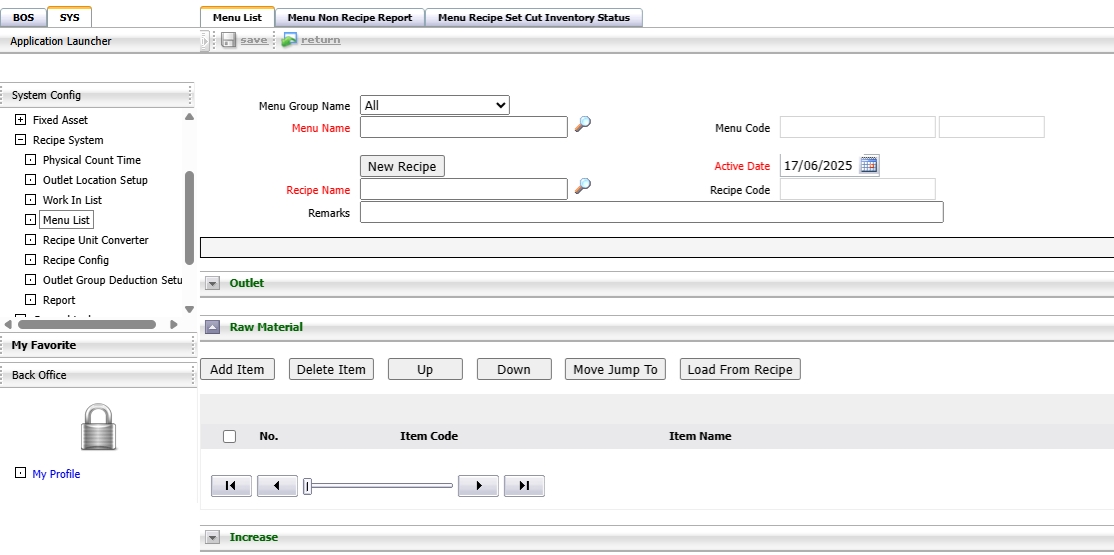

- Navigate to SYS > Back Office Master > Recipe System > Menu List

- Click 'Menu List' tab, then 'New'

- Select main ingredient, store, and add raw materials

- Add hidden costs if applicable via the 'Increase' tab

- Preview and Approve the formula

Note: Only approved formulas can be used in menu recipes.

2.1.4 Report Unformulated Raw Materials:

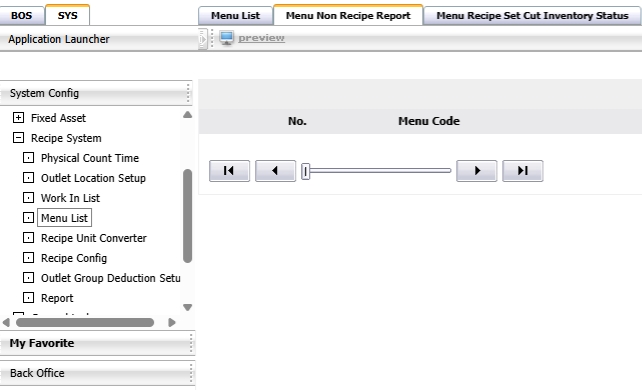

Generates reports listing ingredients not yet defined in any internal formula for review and update.

- Navigate to the report for unformulated ingredients

- View items that have not been defined in any formula

2.1.5 Recipe Determination:

Defines and approves cooking recipes for menu items, linking ingredients and quantities to outlets.

- Navigate to Back Office Master > Recipe System > Menu List

- Click 'New', select menu, define recipe, and save

- Add outlets and raw materials, define quantities

- Click “New Recipe”

- Add hidden costs if any, then Preview and Approve

Note: Approved recipes are required before deducting from sales.

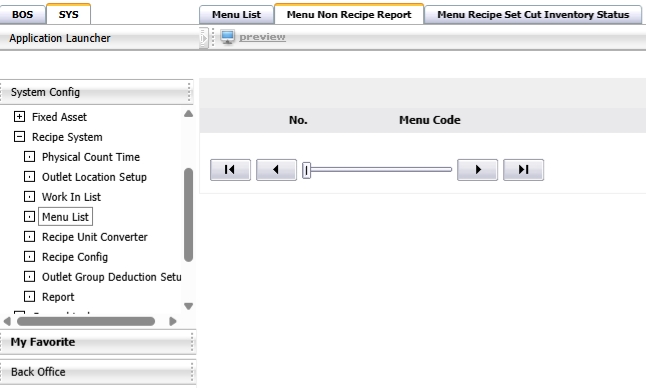

2.1.6 Report on Unformulated Food Menus:

Lists food menus lacking defined recipes to ensure readiness for cost control and deduction.

- View food menus that do not yet have recipes defined

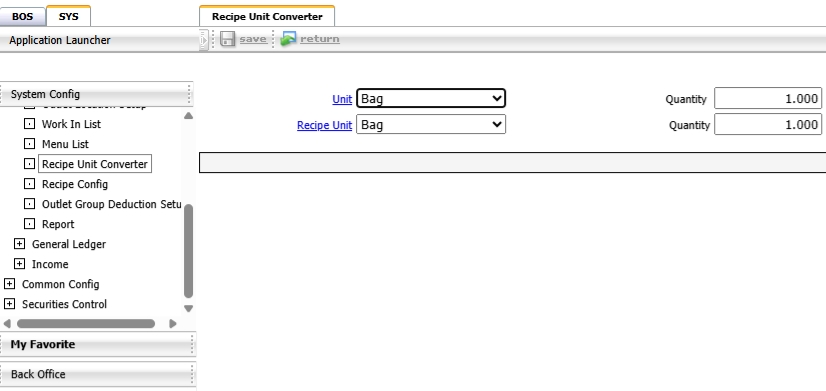

2.1.7 Converting Food Raw Material Units:

Defines unit conversion between stock and recipe units to maintain inventory accuracy.

- Navigate to Convert Food Raw Material Units menu

- Click 'New', select inventory unit and recipe unit

- Press Save

Note: Conversion settings ensure correct stock deduction when units differ.

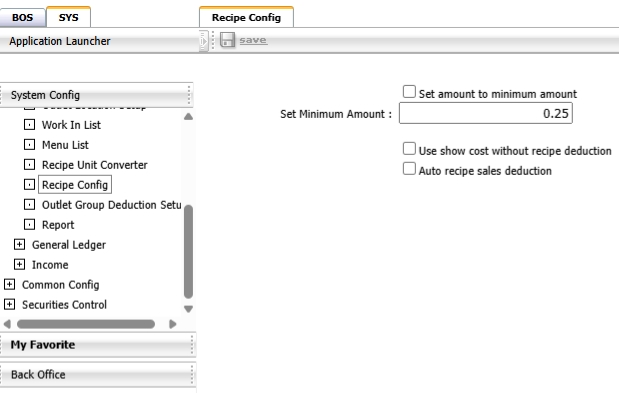

2.1.8 System Setup:

Configures base cost parameters used across the recipe system for consistent cost calculation.

- Define lowest cost settings and press Save

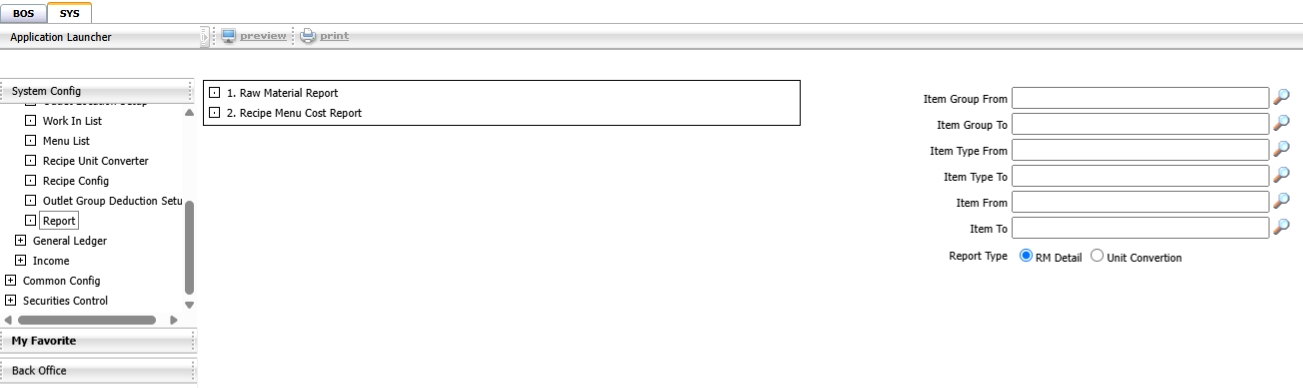

2.1.9 Reports:

Provides summary and detailed reports on raw material usage and recipe cost for financial analysis.

- Raw material report

- Food recipe cost report

3. OPERATION BOS

Available under BOS > Recipe, this section covers the operational features related to daily kitchen workflows, including cooking for stock, cutting ingredients from sales, handling waste or spoiled ingredients, and generating operational reports. These operations help maintain accurate stock levels and track food costs in real-time.

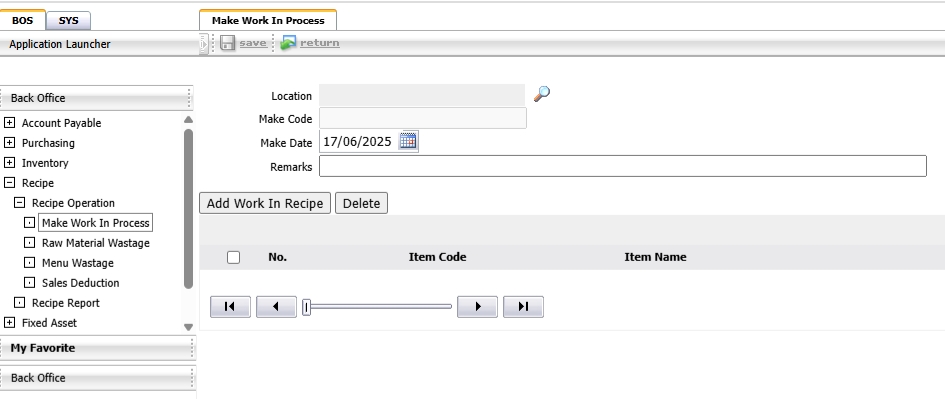

3.1 Cooking Combination

This function allows users to cook menu items and record them as inventory stock. It is often used for items that are prepared in advance and stored. Recipes must be defined and approved before use in this function.

To perform the task:

- Navigate to BOS > Recipe > Recipe Operation > Make Work In Process

- Click 'New'

- Select cooking location and recipe

- Click 'Add Work In Recipe' to add menu item

- Enter cooking quantity

- Click Preview, select cooking date and report format

- Click OK, then Approve

Note: Cooked items will be added to stock and visible in Stock Card reports.

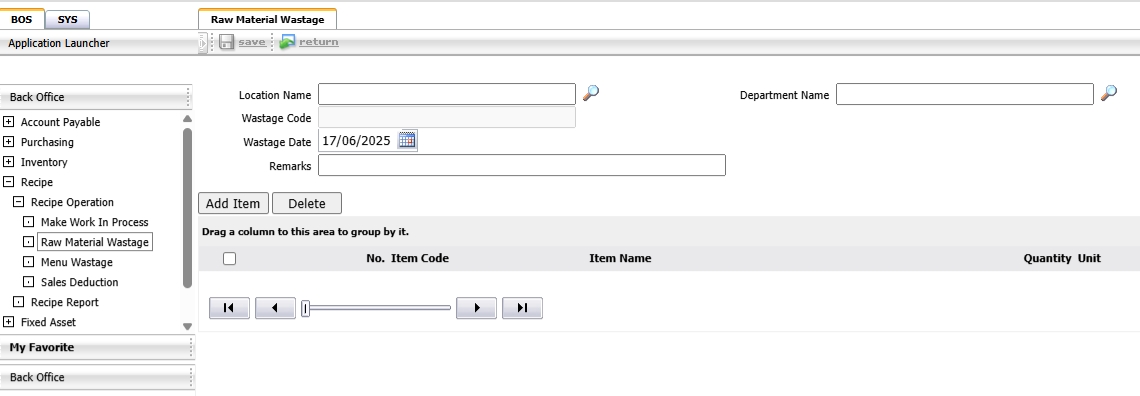

3.2 Raw Materials Wastage

This function allows users to log the disposal of raw materials due to spoilage, expiration, or other waste events. It helps monitor and control inventory loss.

To perform the task:

- Navigate to BOS > Recipe > Recipe Operation > Raw Materials Wastage

- Click 'New', select warehouse and date

- Add waste items and quantities

- Click Save, then Preview and Approve

Note: Waste entries are recorded as cost and displayed in disbursement reports.

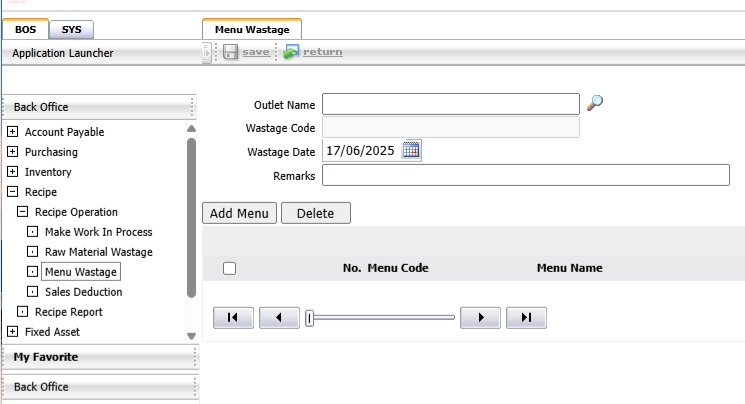

3.3 Menu wastage

This function is used when a prepared menu item is spoiled and needs to be written off as a cost. It ensures that stock and financial reports reflect actual losses.

To perform the task:

- Navigate to BOS > Recipe > Recipe Operation > Menu wastage

- Click 'New', select outlet and waste date

- Add spoiled menu and quantity

- Preview, then Approve

Note: Spoiled items are recorded in Inventory System > Disbursement reports.

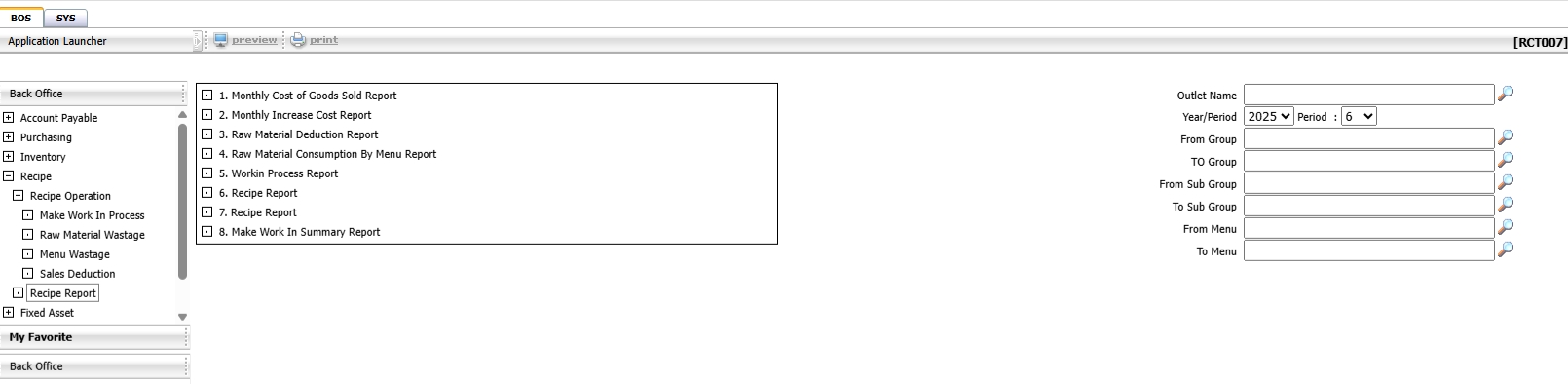

3.4 Reports

The report section in BOS provides insights into cooking combinations, stock movements, raw material usage, and spoiled/wasted items.

To perform the task:

- Navigate to BOS > Recipe > Recipe Report

- Select the report format as needed

Note: Use reports for auditing kitchen activity